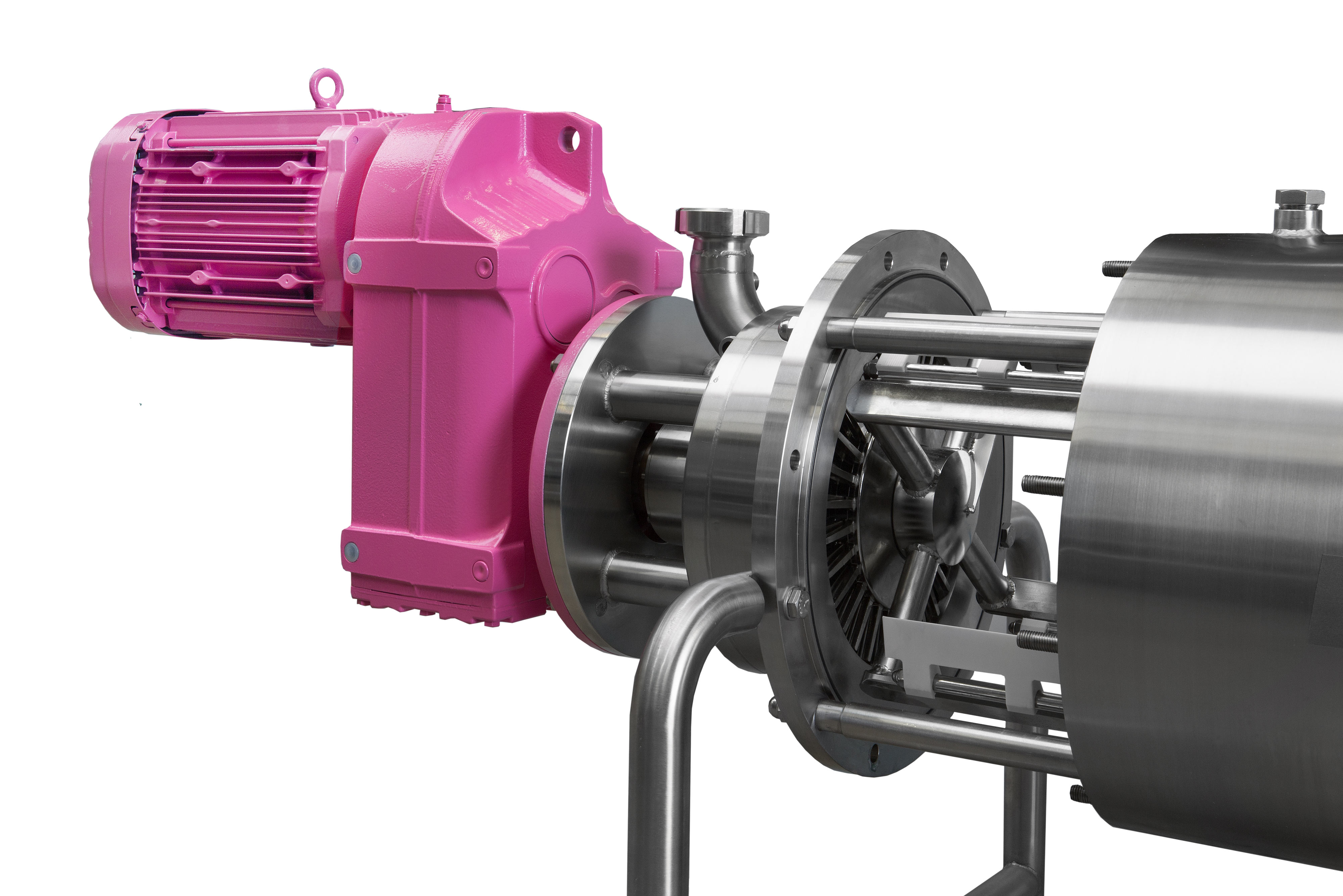

Heat exchanger/ Aerator

We offer our Roto heat exchanger with surface scraping for products for which conventional plate heat exchangers cannot be used. I.e., it is widely used for products with high viscosity (peanut butter, ketchup, petfood), for masses with inclusions like vegetable sauces or fruit compotes and for cooling of fat creams when crystallization occurs. Our Roto heat exchanger is used for pasteurizing water-based creams as well as cooling marshmallow before application. Unique in the industry is our combination of heat exchanger and aerator in one.

Specifications

- Heating and cooling by water

- Capacity: 1.000kg/h

- Horizontal and vertical design

- This system with integrated water tempering, surface scraping, control, CIP and aeration head is unique in the industry

Area of Operation

Manufacturer

Tanis Food Tec was founded in 1991 by Peter Tanis, who still runs the company today, and from the very beginning specialized in continuous and at the same time completely controlled (= control of crystallization, aeration, viscosity, density, capacity, pressure, pH range and temperature) mixing and cooking of all kinds of masses, creams and dairy products. In the course of time, complete, fully automatic lines for the production of marshmallow products were added. In 2021, Tanis teamed up with Orangeworks, a special machine manufacturer for customers such as Mars Wrigley, Kellogg’s, Pepsico and Nestle.